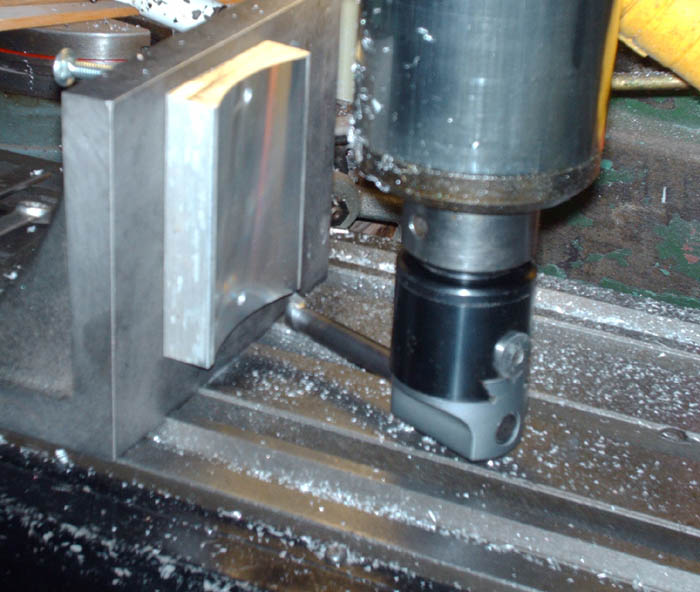

This is the cutting of the rounded edge of a heatsink. We had a project to make a fan for cooling the electronics in a helicopter.

There was not much room and a need for a lot of air flow and high dependability so a 1 1/2 hp, ball bearing, brushless servo

turning at some ungodly RPM was chosen. Because of the need to dissapate heat in the controller, the back of the heatsink

was made to conform to the fan tube. The other side was milled out to accomodate the electronics.

Just to show we have no age or gender bias here is my 90 year old mother running the Lagun mill.